Industrial sorting technology has evolved to utilize non-contact methods for precision and speed. An optical sorting machine represents a significant advancement in this field, operating on a fundamental principle of detecting, analyzing, and separating materials based on their physical properties. The process is a continuous cycle of data acquisition and mechanical action.

The Detection Phase: Image and Light Capture

The initial stage involves sophisticated detection systems. As items move rapidly along a production line, they pass through a viewing area illuminated by consistent lighting. Here, high-resolution cameras or laser sensors scan each object. These sensors capture detailed data, which can include color, shape, structural integrity, and spectral signature. This data forms a digital profile for every item that passes through the optical sorting machine, providing the necessary information for the subsequent decision-making phase.

The Analysis Phase: Real-Time Data Processing

The captured data is instantly transmitted to a centralized computer system equipped with specialized software. This software compares the digital profile of each item against pre-set acceptance parameters. These parameters are defined by operators to identify defects, foreign materials, or specific quality grades. The processing speed of this system is critical, allowing the optical sorting machine to make thousands of these precise comparisons every second without creating a bottleneck in the production flow.

The Separation Phase: Precision Ejection

Once an item is identified for rejection, the system triggers a physical separation mechanism. The most common method involves a precise burst of compressed air. The computer calculates the exact moment the defective item passes over an ejection valve and fires a jet of air to divert it from the product stream. Other systems may use mechanical pushers or flaps. This action ensures that only products meeting the strict quality criteria proceed for packaging, thereby enhancing the overall purity and value of the final output.

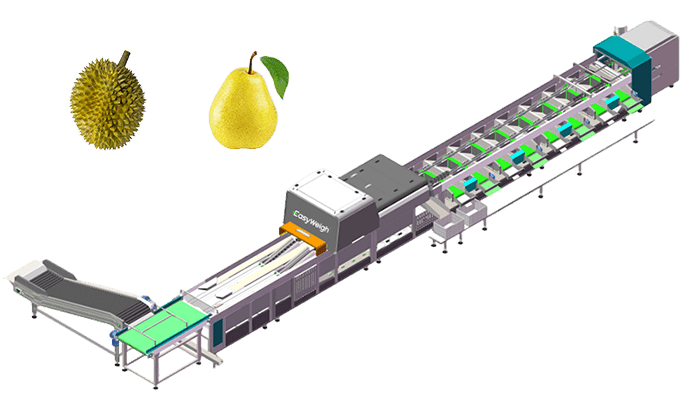

The entire process underscores the non-contact advantage that defines the WEIGHT SORTING system. Without any physical contact, it preserves product integrity by minimizing damage and maximizing accuracy and hygiene. It is this commitment to gentle handling that makes WEIGHT SORTING indispensable for industries where product integrity is paramount.